Sustainable

Farming is a serious business. Because we are what we eat, how we rear our poultry will have an impact on our consumers’ health and lives – now and in the future. For this reason, we take every measure to look for innovative yet sustainable ways to ensure that the food we put on your table is good and healthy.

Advantages of Kee Song’s Proprietary Lactobacillus Feed

To help our chickens grow healthily, we rear our chickens with organic lactobacilli-added feed, which is all-natural.

This feed benefits our organic chickens by strengthening their immunity against diseases, and to have less cholesterol and saturated fat, which make them a better food choice.

The bacteria strain of our lactobacilli-fed chickens also has reduced ammonia and hydrogen sulphide content – a harmful residue which can upset our ecosystem through eutrophication of surface waters and soil acidification.

Spared From Side-Effects of Antibiotics

Reared without antibiotics, our chickens are naturally healthy, and their droppings are free of harmful residues that may affect the surrounding biodiversity as they are leaked into the soil and groundwater. These droppings could then be fermented and combined with lactobacilli to be made into organic fertilisers, thus firming up our approach to pro-eco-farming.

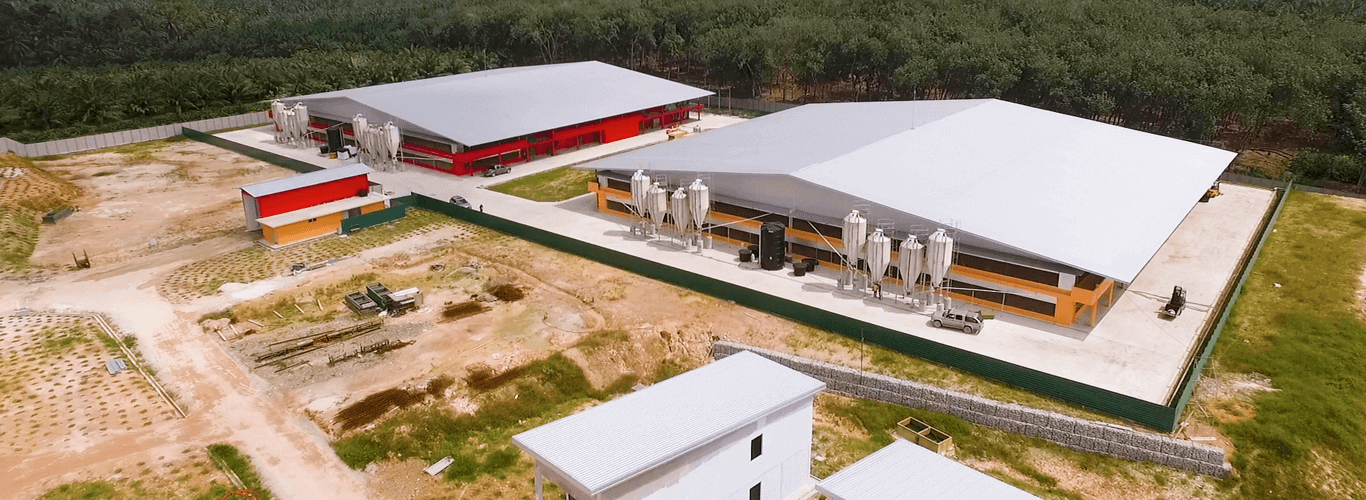

Our Farming

Process

The droppings passed out from Kee Song chickens do not contain antibiotics as its diet is antibiotic-free. Instead, entirely organic, they are fermented for extended days and added with Lactobacillus to produce nutribiotic fertiliser. This organic fertiliser improves the quality of agricultural farm soil and results in fruits and vegetables that are exceptionally fresh and healthy.

Kee Song has been exploring innovative solutions to improve our environment through its sustainable, eco-friendly practices, and will continue to be at the heart of their business directions.

Our

Processes

A fully automated poultry processing system from STORK allows for a production capacity of up to 4000 chickens per hour. All live chickens will be de-feathered, disembowelled and placed in a chilling tank to remove germs and bacteria

With significantly reduced human contact, these precision processing machines fulfil the most stringent hygiene requirements as well as reduce the impact on the environment by controlling waste and pollution effectively. All these efforts have commissioned us to received HACCP and our poultry farms management system is ISO9001 certified UKAS accredited for “Farming of Antibiotics Free Broilers”.

The

Delivery

Processed products are then packed into our delivery trucks before setting off for our vendors. At Kee Song, we have a fleet of more than 20 freezer-equipped delivery vehicles, together with a dedicated team of drivers, to ensure the prompt delivery of our freshly processed products.

Marinating Our Chicken

Products

Adding flavour to our already juicy and tasty chicken meat!

Beyond preserving the shelf life of our products, marinated chicken meat is also infused with greater flavour and an appetising hue, thus raising its overall appeal.

Certified as Halal and to HACCP standards, our marinating facilities are equipped with a massager designed to evenly coat each chicken part with our unique blend of marinades and allow for better absorption of the quality ingredients. The result is perfectly marinated meat that is ready for the stove

For Marinating services in Singapore or inquiries on where to buy marinated meat, please call us at our HOTLINE 6360 0169 or contact us at contact@keesong.com.

Blast

Freezing

Promoting safe and healthy food has always been Kee Song Brothers Poultry top priority. We use the latest technology to preserve and enhance the high quality of our products. Blast freezing allows Kee Song Brothers to lock in and retain the freshness of our meats, thus maintaining quality from our factory to your table.

What Is Blast Freezing?

Blast freezing is a process that rapidly freezes fresh poultry to -18ºC within three to four hours. Supercooled air is blasted within the freezer and circulated by high flow rate axial fans. At a working temperature of -35ºC, it causes heat exchange from the fresh poultry and rapidly absorbs the latent heat from within the meat. This takes place in a controlled environment insulated from the outside elements.

Why are blast frozen products better?

When the meat is frozen, the water inside it crystallises. If freezing takes place at relatively warm temperatures, the ice crystals that form will be massive. Whereas in a blast freezer, the freezing temperature promotes rapid freezing, which creates small ice crystals that have a less damaging impact on the meat. Once the meat has been frozen in a blast freezer, it can be moved to a conventional freezer for storage.

How does blast freezing organic chicken benefit consumers?

Apart from producing high-quality, better-tasting chicken products, blast freezing also promotes food safety. The extremely low temperatures halt bacteria growth, thus significantly reducing the risk of contamination.